MilkTaxi

More than a mobile milk tank:

individual feeding and optimum hygiene

Bucket feeding made easy: feed calves conveniently and quickly, making work enjoyable.

Resource-saving feed costs thanks to pasteurisation of whole milk and use of individual feeding curves.

Precise feed preparation ensures balanced feed and healthy calves. Efficient tank and bucket cleaning ensure optimum hygiene.

New bucket feeding methods

In 2005, Holm & Laue revolutionised bucket feeding with the invention of the MilkTaxi. It put an end to hauling buckets around and ensured that every calf received an optimum mix at just the right temperature. Today, helpful extras such as the electrical drive, the wireless-controlled dosing pump, the possibility of pasteurising and cooling, the hot water heater and the drenching probe for cows have made the MilkTaxi an indispensable tool for modern dairy farms. The latest generation 4.0 has revolutionised bucket feeding yet again. Now, the MilkTaxi permits reliable feeding and weaning depending on calf age – which was only possible with a calf feeder before. It recognises every igloo and calculates the correct current feeding quantity for the calf! This means the MilkTaxi recognises the milk quantity required for the next feed and prepares the mixture step by step, including supplementing through whole milk! This way, faults or carelessness are no longer possible. And the highlight is that all the feeding data can be saved permanently and retrieved at any time via tablet or PC. This allows feeding faults to be localised and eliminated immediately.

Read the following pages to find out which options for the MilkTaxi 4.0 are important for you and how you can reap the benefits.

Simpler Preperation

Many of the strengths of the MilkTaxi are not immediately obvious: how it mixes milk replacer powder lump-free in seconds or gently heats whole milk without it burning surprises everyone who sees the MilkTaxi for the first time.

Powerful base-mounted agitator

The 250 Watt agitator mixes any milk replacer lump-free in seconds. In addition, the agitator supports the heater through short mixing intervals. IMPORTANT: these intervals are adapted to the milk quantity. Its location in the base guarantees maximum working safety and means nothing gets in the way during tank cleaning.

Gentle heater

The MilkTaxi works with a surface heater over the entire base

area. Unlike with spiral heaters, this prevents the occurrence

of “hotspots” where milk can burn and stick. Thus the milk is

heated quickly yet its quality is retained. The display always

informs you of the current temperature of your feed.

Time control

Many functions such as heating and pasteurising can be programmed using a digital timer. The intelligent cooling programme only cools when the tank actually contains liquid which has too high a temperature, and stops cooling in good time before heating in order to save energy costs.

SmartMix

Up to now, there were a lot of potential mistakes to be made during preparation. That is now passé, because the new MilkTaxi guides you step by step to the perfect mixture.

Mixing calculator calf milk replacer

From now on, you define the required CMR concentration (percentage of dry matter content) and your scoop size just once. Then you fill the MilkTaxi up to the required feed quantity. Smart-Mix adds the necessary weight of the CMR automatically and tells you how many scoops of the CMR you need. Even the solubility of the CMR is taken into account, because 20 kg of CMR dissolved in 100 l water is less than 120 l milk (namely 114 l). The MilkTaxi 4.0 automatically corrects this error.

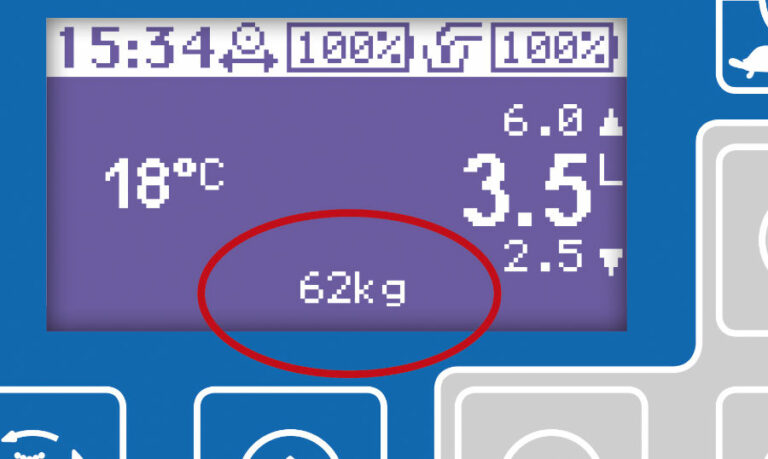

Exact filling level display

The MilkTaxi automatically recognises how much milk or water has already been filled into the tank and shows the current fill quantity constantly on the display.

Whole milk supplement with calf milk replacer

And if whole milk and CMR are to be mixed? What if your milk has a dry matter value of 12.3% but you need an overall mix with 13.5% dry matter? Then SmartMix recognises how much whole milk has been filled and determines how much water and CMR have to be added to get the required milk quantity in the required concentration.

Better Feeding

The saved feed quantities, the remote control with the tubing up to 10 m long and the drip-free dispensing make feeding child’s play.

Simple dispensing

With 9 freely programmable dosing levels you can dispense almost any feed quantity – without any annoying dripping. In addition, the handle has been ergonomically adapted and is nice and light. Thanks to the integrated battery, you are independent of the power supply near the calves. This leaves you completely flexible in your choice of positioning of individual igloos and allows you to feed calves in different places.

Wireless remote control

With the remote control on the dispensing arm you can conveniently feed even the calves that are up to 10 m away from the MilkTaxi without needing a cable. It goes without saying that the quantities can be adapted individually at the dispensing arm in this case too.

Statistics function

You can check the most important work steps in the MilkTaxi’s display menu using a special statistics function. Every pasteurising cycle, every feeding and every cleaning is documented. This information is still available even weeks later through a calendar function, allowing you to check the workflows on your farm perfectly.

SmartID

During feeding you keep asking yourself how old this particular calf is and how much milk it should be getting. This is no longer necessary, because the MilkTaxi recognises every pen and the calf’s age.

Wireless detection of the calf pens

The MilkTaxi detects each pen wirelessly as it moves past and the pen number is shown on the display. The operator now selects the right amount of feed for the calf or group of calves, presses the release button, which causes the milk to be filled into the buckets. The weight fed is registered and stored for each pen.

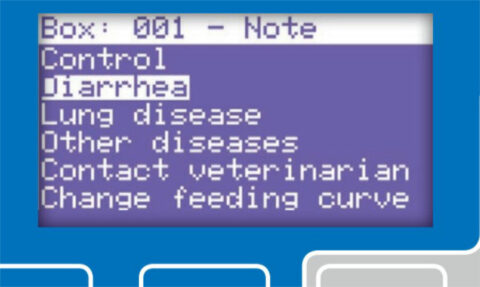

Intelligent pen management

Smart-ID works both for single and group pens. For groups of calves, it indicates how many calves are in the group and whether they are fed using individual buckets or “teat bars” When used in conjunction with the CalfGuide management application, information can be stored for individual pens and automatically retrieved at the next feeding. This is how staff members are alerted to sick animals or other unusual circumstances. An enormous improvement in work quality, particularly where there are changes in staff.

Easier Transportation

Easy milk transportation has been THE great help for our customers for more than 10 years now.

Stable 4-wheel undercarriage

The MilkTaxi is extremely stable on 4 wheels with a low centre of gravity. It does not topple over even when moved quickly, over uneven terrain and full. Thanks to the 40 cm front wheels and the large ground clearance, unevenness or small thresholds are not a problem. The 260 l model is also available as a single-axle trailer as an alternative.

EL-AN electrical drive

You can move all models forwards and backwards at two different speeds using the stepless electrical drive. This not only makes calf feeding fun, but it also goes easy on your back.

HeavyGrip

The new, well-gripped tyres for the MilkTaxi provide grip on slippery surfaces or steep terrain. Almost better than driving a tractor!

Failsafe tyres

They’re unbreakable! No nasty surprises with flat tyres. The elastic filling of the wheels offers the best conditions for stony tracks.

Pasteurising

Mastitis bacteria play an important role in illnesses in the calf pen too. Pasteurising eliminates up to 99.5% of these bacteria and is already part of the calf feeding standard on many dairy farms.

Pasteuriser

During pasteurising using the so-called batch method, dangers pathogens are destroyed to 99.5% at a temperature of 63 °C over 35 minutes. As an alternative to this program, the MilkTaxi offers two different heat treatment methods at 60 °C over 60 or 70 minutes. All the starting times can be freely programmed. The result is that the milk has already been pasteurised when you arrive in the barn for feeding in the morning.

Automatic cooling function

With the MilkTaxi pasteuriser water cooling is part of the standard package. This allows the milk to be stored fresh until feeding or pasteurising. The automatic cooling programs are particularly practical when robotic milkers are used. It records the fill level and temperature for automatic filling. In addition, the cooling process is programmed in such a way that it makes optimum use of the required energy.

Hot water heater

If you want to cut costs on energy and if you have plenty of hot water, then an optional hot water heater saves expensive energy costs otherwise incurred for heating the milk.

Comfortable work

At the end of the day, it is the convenience that makes your work easier. From user-friendly display and easy cleaning to applications beyond calf feeding: you won’t want to be without your MilkTaxi.

Glove compartment – for small and large aids

This practical storage box offers space for all the small tools needed in the calf pen. Everything has its place in the practi-

calf glove compartment, whether ear tag pliers, thermometer, weight tape measure, disposable gloves, barn lists or other important items. What is more, the level cover serves as an excellent writing surface. All these things are quickly at hand in other places because the entire box can be detached from the MilkTaxi and transported very easily.

Bucket transport

The hinged frame, allowing you to transport up to two milk churns, is particularly practical. It can also be used for moving other things such as dry feed or tools. The 8 l colostrum jugs are particularly practical. Inserted in the larger churn with hot water, the milk remains at the perfect temperature before it is fed to the calves.

Cleaning and hygiene

FlushMaster bucket cleaning

Cleaning feed buckets is time-consuming, as you have to collect the buckets and take them to the washing area. The FlushMaster allows you to clean the buckets using a rotating nozzle in the MilkTaxi, directly at the calf pen. The FlushMaster is also ideal for thorough tank cleaning, leaving a clean interior from cover to base. This practical aid can be retrofitted to all MilkTaxi models with a pump.

Automatic cleaning

Since the cover can be fully opened, cleaning of the tank is extremely easy. The semi-automatic cleaning program guarantees optimum hygiene. Residual quantities can be emptied completely, even from the pump and hose. Supplementary cleaning with a brush improves the result, and your MilkTaxi is ready to go again after just a few minutes.

FoodSafe.

Do you sell some of your milk directly? The FoodSafe edition of your MilkTaxi is also suitable for transporting food, enabling you to transport your milk easily and hygienically from the milk tank to the milk filling station. All components used comply with the specifications of the German Food, Commodities and Feed Code (according to VDE Prüf- und Zertifizierungsinstitut GmbH).

Perfectly Illuminated

It is often pretty dark in the early morning hours or in the winter months. Nevertheless, the MilkTaxi will make light work for you.

Lights off – spotlight on

The SpotLight mounted on top of the MilkTaxi brings light into the darkness: the completely flexible gooseneck provides a 360° all-round view at working height.

Dark? No problem

Thanks to the integrated LED drive light you always see where you are going. So feeding calves in more remote calf hutches in the evening is no problem.

Useful accessories

And there are even more special options for the Holm & Laue MilkTaxi: for example, a jacket or drenching set.

MilkTaxi jacket

Calf milk can cool down between warming and feeding on particularly cold days. Our new jacket for the MilkTaxi keeps it warm for about twice as long as without the jacket, accordingto our own trials (in the trial at – 13 °C, the milk lost about 1°C after 8 minutes without the jacket, but only after about 17 minutes with the jacket).

Drenching cows

A cow drenching option is also available. The drenching fluid can be ideally mixed and temperature-controlled in the MilkTaxi, transported to the cows and then gently drenched into the rumen via the pump. Rather than struggling with a manual pump, you can focus completely on the cow thanks to the MilkTaxi.

MilkTaxi 400 Litres

The large trailer model for up to 100 calves or 800 litres of feed per day (2 x 400l).

Would you like a little more?

Sometimes even the largest MilkTaxi to date with 260 l is not enough. This is not only because farms are getting bigger, but also because more milk is being fed per calf. The 400 litre MilkTaxi now also offers larger farms virtually all the advantages that the tried and tested smaller models have. Even the pasteurisation function is available as an option, leaving nothing to be desired with the 400 model.

Made for rugged surroundings

The MTX 400 is built particularly sturdily not only because of its higher payload. The spring-loaded axle ensures that the transport of milk to the calves is steady and smooth, especially on uneven tracks.

MilkTaxi Dosing Unit

Do you already have a mobile milk tank and would like to use it as a “MilkTaxi”? The MilkTaxi’s dosing unit makes this possible.

MilkTaxi XXL

If the tried and tested MilkTaxi models are not large enough, the dosing unit offers an ideal opportunity to convert existing milk tanks into an XXL MilkTaxi. The dosing unit consists of the battery-operated pump with dispensing arm. Display and control element are conveniently integrated in a separate unit in the driver’s cab.

Temperature and fill level measurement

The dosing unit also measures the milk temperature and determines the fill quantity in the tank by means of the integrated SmartMix sensor. This means that all sizes of farm can benefit from the advantages of precise dosing and optimum temperature control when feeding their calves. Turn your tank into a MilkTaxi XXL!

Options and features

MilkTaxi basic configuration

- MilkTaxi model version 100 l, 150 l and 260 l with stable and manoeuvrable chassis on 4 wheels; front tyres 40 cm

- Electronic control with liquid level sensor, thermometer and statistics function

- Powerful base-mounted agitator mixing at regular intervals in heating mode

- MilkTaxi, model version 260 l and 400 l, built as a trailer with jack wheel

- Tank made of easy-to-clean, polished stainless steel

- Lockable lid with sealing ring; opens to full radius

- 1 1⁄4″ drain tap for complete draining

- LED headlight

- Semi-automatic cleaning program

MilkTaxi pasteuriser basic configuration

- MilkTaxi model version 100 l, 150 l and 260 l with stable and manoeuvrable chassis on 4 wheels; front tyres 40 cm

- Electronic control with liquid level sensor, thermometer and statistics function

- MilkTaxi, model version 260 l and 400 l, built as a trailer with jack wheel

- Tank made of easy-to-clean, polished stainless steel

- Lockable lid with sealing ring; opens to full radius

- 1 1⁄4″ drain tap for complete draining

- LED headlight

- Semi-automatic cleaning program

- Pumping, mixing, heating as standard

- Up to 6 programmable pasteurising start-up times

- Integrated water cooling

- Three selectable programs: 65 °C for 35 minutes, 60 °C for 60 minutes, 60 °C for 70 minutes

MilkTaxi options

- Floor heating (3 kW, 5 kW, 6 kW or 9,7 kW)

- Pump with dispensing arm

- Wireless remote control dispensing arm

- EL-AN electrical drive

- HeavyGrip tyres

- Failsafe tyres

- Smart-Mix

- Smart-ID

- Tilt-up churn support frame for two 30 l milk churns

- Colostrum jug

- SpotLight

- FlushMaster

- Glove compartment

- Cow drenching function

- FoodSafe food approval

- MilkTaxi jacket

- CalfGuide for MilkTaxi

MilkTaxi pasteuriser options

- Wireless remote control dispensing arm

- EL-AN electrical drive

- HeavyGrip tyres

- Failsafe tyres

- Smart-Mix

- Smart-ID

- Tilt-up churn support frame for two 30 l milk churns

- Colostrum jug

- SpotLight

- FlushMaster

- Glove compartment

- Cow drenching function

- FoodSafe food approval

- MilkTaxi jacket

- CalfGuide for MilkTaxi

- Hot water heating

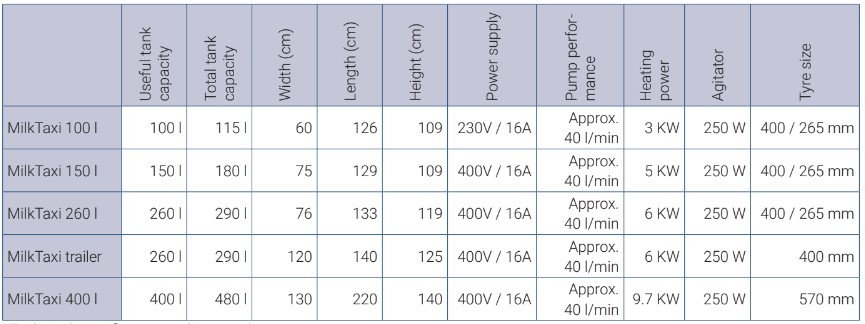

MilkTaxi technical specifications

*Technical specifications subject to change